What is Carbon Capture?

Carbon Capture is the first step of the CCUS (carbon capture, utilisation and storage) cycle. The process involves capturing carbon dioxide (CO₂) generated by large point sources or from the atmosphere.

Carbon Capture, Utilisation and Storage (CCUS) Cycle. Source: IEA

There are two ways to capture carbon:

1. Point of source capture

2. Direct air capture (DAC)

Point of source capture

Large point sources use conventional sources of energy like fossil fuels or biomass. For heavy-emitting industries like power, steel, cement, oil and gas, and chemicals, carbon capture has the potential to radically reduce environmental footprints, capturing more than 90% of carbon dioxide emissions.

This can be further classified into three: pre-combustion capture, post-combustion capture and oxy-combustion capture.

1. Pre-combustion capture - Involves capturing CO₂ prior to the fuel being used. The fuel is reacted with air and then steam to produce CO₂ and H₂. The CO₂ is removed from the mixture and hydrogen is used as fuel.

2. Post-combustion capture - Using solvents to capture CO₂ from flue gas in industrial plants.

3. Oxy-combustion capture - Oxygen is used for combustion as opposed to air. This results in flue gas that consists mainly of CO₂.

This CO₂ can be utilised on-site or stored. Since this method prevents generated CO₂ from going into the atmosphere, it can retrofitted to existing facilities to allow for their continued operations. Heavy industries where emissions cannot be reduced like chemicals, steel, cement, etc can benefit from point of source capture of carbon.

A notable example is Aker Carbon Capture which has retrofitted its cement plants and refineries with point of source capture mechanisms responsible for preventing 2.2Mt of CO₂ from being released into the atmosphere every year.

Technology used

1. Solvent-based CO₂ Capture

Involves absorption of CO₂ into a liquid carrier. Alkanolamines are the most well-known solvents used for CO2 absorption over the years. Intensive research into advanced solvents is underway with a focus on water-lean solvents, phase-change solvents and high performance functionalised solvents. The aim is to have a lower regeneration energy requirement than existing amine systems combined with high CO2 absorption capacity to lower capture cost.

2. Sorbent-based CO₂ Capture

Involves adsorption of CO₂ using a solid sorbent. Solid adsorbents have lower regeneration energy requirements and better adsorption capacity selectivity as compared to amine based systems. Recently research on mesoporous silicas, zeolites, and metal-organic frameworks (MOFs) and ionic liquids have shown varying degrees of success for CO₂ capturing and removal. Research aims to develop low-cost durable sorbents that have high selectivity and capacity for adsorption of CO₂, resistance to oxidation, and ability to withstand multiple regeneration cycles.

3. Membrane-based CO₂ Capture

Uses permeable or semi-permeable materials that allow selective separation of CO₂. The advantages of employing membrane process include no use of hazchem or emission issues, a reduced plant footprint and efficient partial CO₂ capture. Ongoing research is focussed on developing durable membranes at a low-cost that showcase improved permeability and selectivity for CO₂, thermal and physical stability, and tolerance to gas contaminants. Examples are polymeric membranes, mixed matrix membranes, sub-ambient temperature membranes etc.

4. Novel Concepts

Include alternative technologies and processes, such as cryogenic separation and electrochemical membranes.

5. Hybrid Systems

Efficiently combine two key technologies in a single system (e.g., sorbent-membrane system). They can become a cost-effective system by reducing the overall energy intake of the process. This is done by efficiently leveraging process synergies.

Direct Air Capture (DAC)

The primary difference between direct air capture (DAC) and point of source capture is when the CO₂ is captured. DAC captures carbon after it has been released into the atmosphere by extracting CO₂ directly from the atmosphere preferably by using renewable energy, energy-from-waste, or other waste heat as energy sources. The advantage of this methods is that it is completely source independent and can be located anywhere. Once absorbed, the CO₂ is transported to facilities that utilise it or stored permanently.

Climeworks is a DAC+Storage (DAC+S) technology company that captures 40kt of CO₂ every year and stores it inside rocks through its partner Carbfix

Technology used

We have two technological approaches currently employed

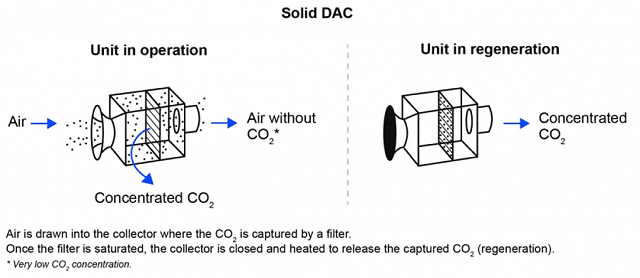

1. Solid Direct Air Capture (S-DAC)

- Uses solid adsorbents operate at ambient to low pressure (i.e. under a vacuum) and medium temperature (80-120 °C) that act as filters that bind with CO₂.

- When these filters are full of air, the units that house the fans are closed and heated. When heated, the filters release the concentrated CO₂ which can be captured for storage or use.

- An S-DAC plant comes in modular design, are small and scalable. For instance, the biggest operating S-DAC plant captures 4,000 tons of CO₂ a year.

Source: Carbon Credits

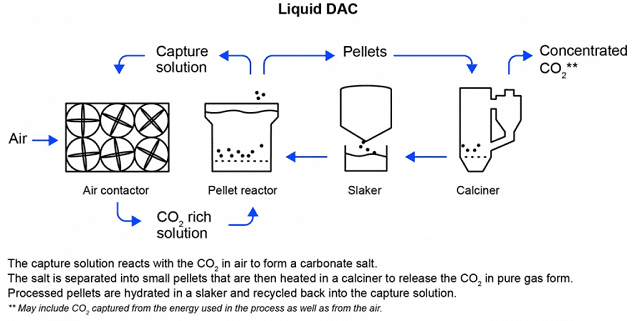

2. Liquid Direct Air Capture (L-DAC)

- L-DAC is based on two closed chemical loops. The first loop occurs in the contactor unit which brings the air into contact with potassium hydroxide. The second loop releases the captured CO₂ from the solution in a series of units operating at high temperatures (300°C – 900°C).

- L-DAC plants suit large-scale operations and can capture about 1 MtCO₂/year

Source: Carbon Credits

CO₂ concentration in the atmosphere is significantly lesser than flue gas in industries making DAC an energy intensive and expensive process as compared to point of source capture. As DAC technology has yet to be demonstrated on a large scale, its costs are uncertain. Capture cost estimates range anywhere from $200/t – $700/t.

Leading Carbon Capture Companies

The first carbon capture plant, Sleipner CO₂ gas processing and capture unit, began operations in 1996 in Norway. About 1 million metric tons of CO₂ (equivalent to about 3% of Norway’s total annual CO₂ emissions) have been sequestered annually at Sleipner since October 1996.

|

Company |

HQ |

Achievements |

Type |

|

Climeworks (2009) |

Switzerland |

Total Capacity ~ 40kt CO₂ / year Arctic Fox - 50t CO₂ / year Orca - 4kt CO₂ / year Mammoth - 36kt CO₂ / year 2050 - Scale to Gt CO₂ / year |

Direct Air Capture + Storage |

|

Aker Carbon Capture (2020) |

Norway |

Total Capacity ~ 2.2Mt of CO₂ / year Ørsted Kalundborg CCS - 500k CO₂ / year Brevik Cement Plant - 400k CO₂ / year Twence CCU - 100k CO₂ / year Forus Energigjenvinning - 100k CO₂ / year Preem refinery - 600k CO₂ / year Amager Bakke (Ski Slope) - 500k CO₂ / year |

Source Capture + Storage + Utilisation |

|

LanzaTech (2014) |

Illinois, USA |

Developed process to recycle CO₂ to Omega-3 fatty acids Constructed the world’s first refinery gas to ethanol plant Produced 20M gallons of ethanol in China (preventing emissions equivalent to 100kt of CO₂) Set up waste to ethanol facility in Japan |

Source Capture + Fuel conversion |

|

Engineering (2009) |

Canada |

1Mt of CO₂ / year from 2025 |

Direct Air Capture + Air to Fuel conversion |

|

Iceland |

• 12kt of CO₂ / year turned into stone • 70kt of CO₂ turned into stone from 2014 |

Direct Air Capture + Storage |

References

[1] S. Budinis, M. Fajardy, and C. Greenfield, “Carbon Capture, Utilisation and Storage - Energy System,” IEA, Jul. 11, 2023. https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage

[2] MIT Climate, “How much carbon dioxide would we have to remove from the air to counteract climate change?,” MIT Climate Portal, Oct. 26, 2023. https://climate.mit.edu/ask-mit/how-much-carbon-dioxide-would-we-have-remove-air-counteract-climate-change

[3] National Energy Technology laboratory, “Point Source Carbon Capture Program,” netl.doe.gov. https://netl.doe.gov/carbon-management/carbon-capture

[4] T. N.Borhani and M. Wang, “Role of Solvents in CO2 Capture processes: the Review of Selection and Design Methods,” Renewable and Sustainable Energy Reviews, vol. 114, p. 109299, Oct. 2019, doi: https://doi.org/10.1016/j.rser.2019.109299.

[5] M. Khraisheh, F. Almomani, and G. Walker, “Solid Sorbents as a Retrofit Technology for CO2 Removal from Natural Gas under High Pressure and Temperature Conditions,” Scientific Reports, vol. 10, no. 1, Jan. 2020, doi: https://doi.org/10.1038/s41598-019-57151-x.

[6] D. Adams and J. Davison, “Capturing CO2,” Global CCS Institute, Jul. 2007. Available: https://www.globalccsinstitute.com/archive/hub/publications/95741/capturing-co2.pdf

[7] Carbon Engineering, “Direct Air Capture Technology | Carbon Engineering,” Carbon Engineering. https://carbonengineering.com/our-technology/

[8] Climeworks, “Direct Air Capture Technology and Carbon Removal,” climeworks.com, 2023. https://climeworks.com/direct-air-capture

[9] S. Budinis, “Direct Air Capture - Energy System,” IEA, Jul. 11, 2023. https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage/direct-air-capture

[10] Business Wire, “Twelve to Deploy World’s First Industrial-Scale Carbon Transformation Platform,” www.businesswire.com, Jun. 29, 2022. https://www.businesswire.com/news/home/20220629005271/en/ (accessed Mar. 19, 2024).

[11] Global Cement staff, “Skyonic Opens commercial-scale Carbon Capture Unit at Capitol Aggregates Cement Plant,” www.globalcement.com, Oct. 22, 2014. https://www.globalcement.com/news/item/2980-skyonic-opens-commercial-scale-carbon-capture-unit-at-capitol-aggregates-cement-plant (accessed Mar. 19, 2024).

[12] Datong Foreign Investment Promotion Bureau, “国内首套化学链矿化CCUS项目在大同投运! - 部门动态 - 大同市人民政府门户网站,” Dt.gov.cn, 2023. https://www.dt.gov.cn/dtszf/bumdtcm/202301/1dec6bfaf1e84fbdb72ffc8bf5da2651.shtml (accessed Mar. 19, 2024).

[13] Carbon8, “Carbon8’s CO2ntainer Completes Its Journey to Vicat’s Montalieu Cement Plant,” Carbon8. https://www.carbon8.co.uk/news/carbon8-systems-co2ntainer-completes-its-journey-to-vicats-montalieu-cement-plant (accessed Mar. 19, 2024).

[14] Geoscience Australia, “Carbon Capture and Storage (CCS),” www.ga.gov.au, Mar. 16, 2021. https://www.ga.gov.au/scientific-topics/energy/resources/carbon-capture-and-storage-ccs

[15] Geoscience Australia, “Current Projects,” www.ga.gov.au, Mar. 16, 2021. https://www.ga.gov.au/scientific-topics/energy/resources/carbon-capture-and-storage-ccs/current-projects

[16] B. James, “Energy Fundamentals of Carbon Capture,” Share Your Green Design, Aug. 02, 2023. https://www.shareyourgreendesign.com/energy-fundamentals-of-carbon-capture/ (accessed Mar. 20, 2024).

[17] Senate Democrats, “SUMMARY: THE INFLATION REDUCTION ACT OF 2022,” 2022. Available: https://www.democrats.senate.gov/imo/media/doc/inflation_reduction_act_one_page_summary.pdf

[18] N. R. Canada, “CCUS RDD Call,” natural-resources.canada.ca, Jul. 26, 2021. https://natural-resources.canada.ca/science-and-data/funding-partnerships/opportunities/grants-incentives/energy-innovation-program/ccus-rdd-call/23815

[19] McKinsey & Company, “The World Needs to capture, use, and Store CO2 | McKinsey,” www.mckinsey.com. https://www.mckinsey.com/industries/oil-and-gas/our-insights/the-world-needs-to-capture-use-and-store-gigatons-of-co2-where-and-how

[20] A. de la Garza, “The Inflation Reduction Act Is a Carbon Capture Bonanza,” Time, Aug. 11, 2022. https://time.com/6205570/inflation-reduction-act-carbon-capture/

[21] CCST @ MIT, “What Future for Carbon Capture and Sequestration?,” Apr. 2001. Available: https://sequestration.mit.edu/pdf/EST_web_article.pdf

[22] Center for Climate and Energy Solutions, “Carbon Capture,” Center for Climate and Energy Solutions, Apr. 11, 2018. https://www.c2es.org/content/carbon-capture/

Senate Democrats 2022, SUMMARY: THE INFLATION REDUCTION ACT OF 2022.